Welcome to the official website of Weifang Haofeng Electromechanical Equipment Co., Ltd!

CONTACT US

Tel:+86-15898948860 / +86-15288998855

E-mail:hfzhuqihang@gmail.com

Company address: Yuhe Subdistrict, Weicheng District, Weifang City, Shandong Province

Mixed flow closed cooling tower

Category:

Keywords:

Mixed flow closed cooling tower

E-MAIL:

Product details

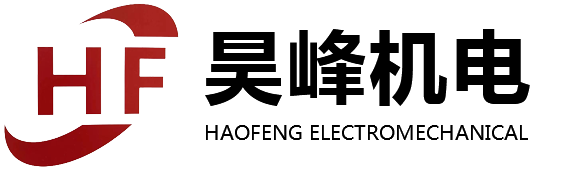

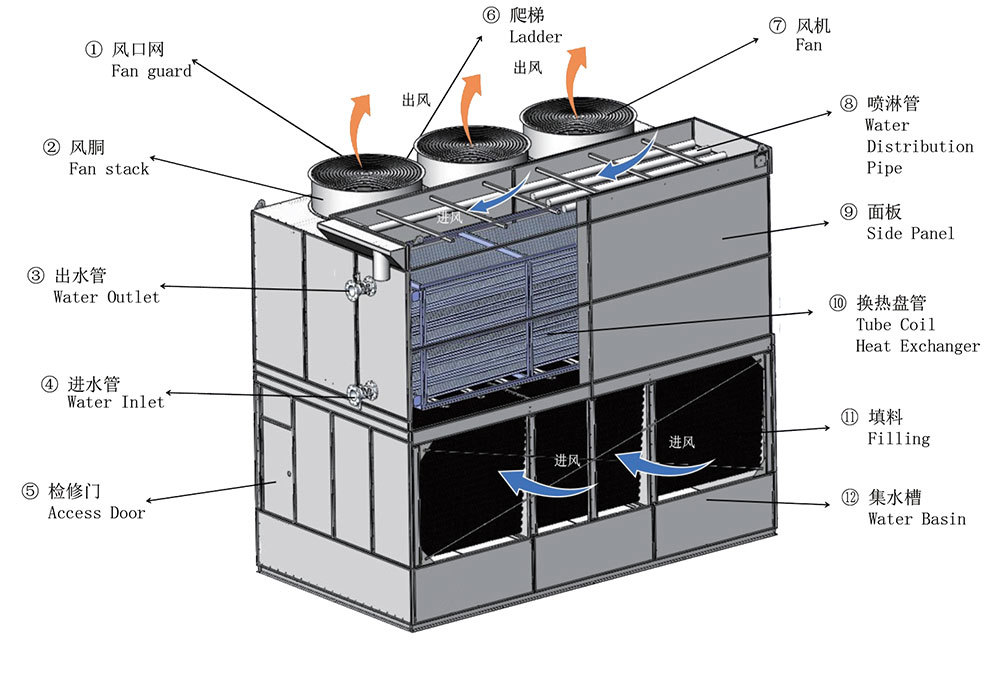

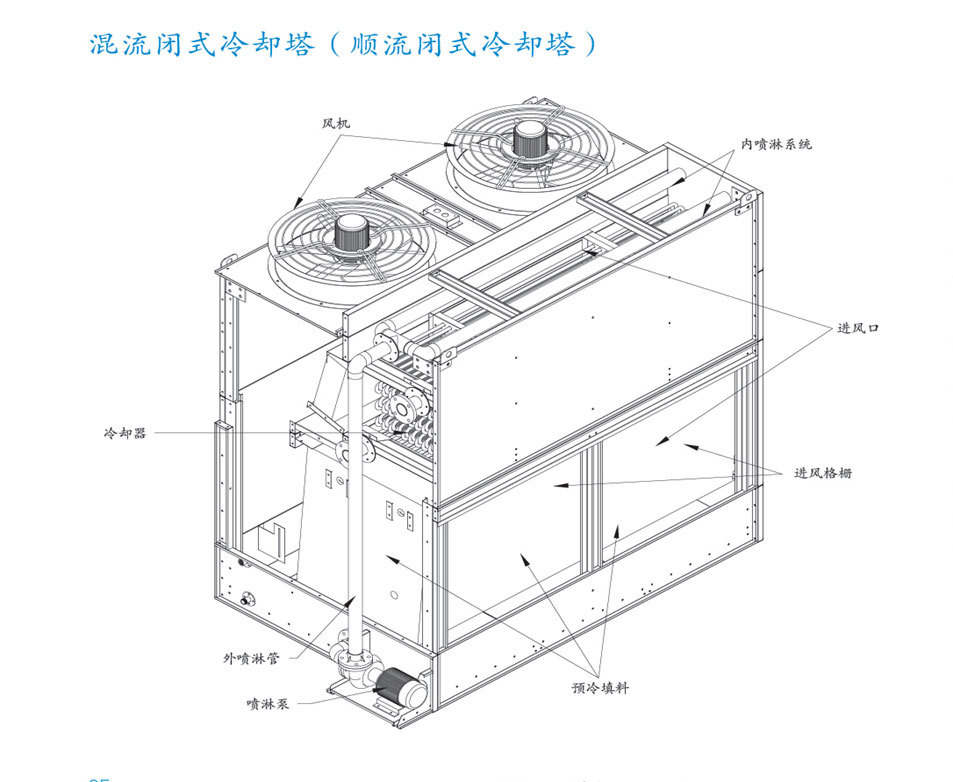

The natural wind enters from two directions, one direction is from the top of the cooling tower into the air inlet, through the cooler into the air duct, the other direction is from the air inlet grille, through the pre-cooling packing into the air duct, the two directions of the wind gathered together, through the exhaust system will be discharged to the cooling tower above.

The spray pump absorbs water from the tank, through the external spray pipe to the internal spray device, down evenly sprayed on the cooler, and then fall on the pre-cooling filler, and finally fall into the tank.

The direction of wind flow is perpendicular to and in the same direction as the falling direction of spray water, so it is called mixed flow closed cooling tower. (Some manufacturers named the flow, is cooler as a reference)

Mixed-flow closed cooling towers can also be made into double-side mixed-flow closed cooling towers, and cross-flow closed cooling towers can also be made into single-side cross-flow closed cooling towers.

| Mode No. | Cooling capacity (kcal/h) |

Main circulating pump | Fan | Spray pump | Connecting pipe (mm) |

Equipment size (mm) |

Net weight (Kg) |

||||||

| Power (kw) |

Air Volumn (m³/h) | Power (kw) |

Flow (m³/h) |

Power (kw) | In and out | Make UP | Drain | L | W | H | |||

| HFB-50T | 250000 | 5.5*2 | 22000*2 | 1.5*2 | 53 | 1.1 | DN65 | DN25 | DN32 | 2500 | 2300 | 2800 | 1100 |

| HFB-80T | 400000 | 7.5*2 | 22000*2 | 1.5*2 | 70 | 1.5 | DN80 | DN25 | DN32 | 2800 | 2300 | 2800 | 1400 |

| HFB-100T | 500000 | 11*2 | 22000*3 | 1.5*3 | 80 | 2.2 | DN100 | DN32 | DN32 | 3400 | 2300 | 3000 | 1800 |

| HFB-150T | 750000 | 15*2 | 34000*3 | 2.2*3 | 150 | 3 | DN100 | DN40 | DN50 | 3900 | 2500 | 3000 | 2400 |

| HFB-180T | 900000 | 22*2 | 34000*3 | 2.2*3 | 150 | 3 | DN125 | DN40 | DN50 | 4000 | 2500 | 3300 | 2800 |

| HFB-200T | 1000000 | 22*2 | 35000*3 | 3*3 | 180 | 4 | DN150 | DN40 | DN50 | 4500 | 2500 | 3300 | 3000 |

| HFB-260T | 1300000 | 37*2 | 35000*3 | 3*3 | 233 | 5.5 | DN200 | DN50 | DN65 | 4500 | 2800 | 3300 | 3400 |

| HFB-300T | 1500000 | 37*2 | 35000*4 | 3*4 | 286 | 7.5 | DN200 | DN50 | DN65 | 5000 | 2800 | 3300 | 3900 |

| HFB-350T | 1750000 | 45*2 | 50000*4 | 3*4 | 286 | 7.5 | DN250 | DN65 | DN50*2 | 5500 | 3000 | 3500 | 4500 |

| HFB-400T | 2000000 | 55*2 | 55000*4 | 4*4 | 150*2 | 3*2 | DN250 | DN65 | DN50*2 | 6000 | 3000 | 3500 | 5200 |

| HFB-450T | 2250000 | 55*2 | 50000*5 | 3*5 | 180*2 | 4*2 | DN300 | DN65 | DN50*2 | 7000 | 3000 | 3500 | 6000 |

| HFB-500T | 2500000 | 45*3 | 65000*6 | 4*5 | 233*2 | 5.5*2 | DN300 | DN50*2 | DN50*2 | 7000 | 3300 | 4200 | 6500 |

| HFB-600T | 3000000 | 55*3 | 65000*6 | 4*6 | 286*2 | 7.5*2 | DN300 | DN50*2 | DN50*2 | 8000 | 3300 | 4200 | 7200 |

Note: The above dimensions refer to the dimensions of the host; All models and dimensions can be customized.

The configuration of the auxiliary water tank is as follows:

| 50T-100T:1100-1000-1800(0.5m³water tank); 100-200T:1700-1100-1800(1.0m³water tank); Water tank rack height | ||||||||||||

| 180T-260T:2000-1600-1600(1.5m³water tank); 240-300T:2100-2100-1600(2.0m³water tank) Water tank laid flat | ||||||||||||

| 320T-400T:2300-2100-1800(3.0m³water tank); 450-600T:2500-2100-2200(4.0m³water tank) Water tank laid flat | ||||||||||||

Online consultation

Attention: Please leave your email and our professionals will contact you as soon as possible!

Related products

CONTACT US

Address: Yuhe Subdistrict, Weicheng District, Weifang City, Shandong Province

PRODUCTS