Welcome to the official website of Weifang Haofeng Electromechanical Equipment Co., Ltd!

CONTACT US

Tel:+86-15898948860 / +86-15288998855

E-mail:hfzhuqihang@gmail.com

Company address: Yuhe Subdistrict, Weicheng District, Weifang City, Shandong Province

Counterflow closed cooling tower

Category:

Keywords:

Counterflow closed cooling tower

E-MAIL:

Product details

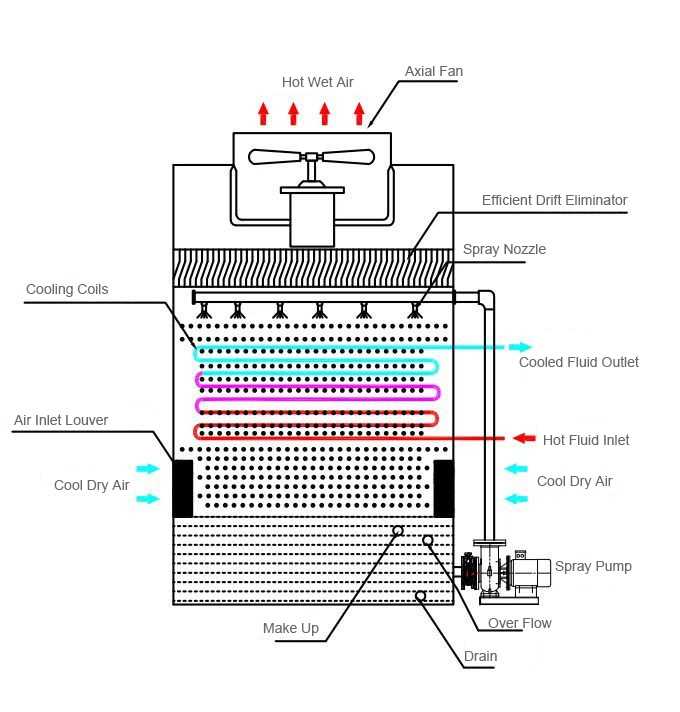

Natural wind enters the cooling tower through the inlet air louvers, flows upward, and is discharged from the top of the cooling tower through the exhaust system.

The spray pump draws water from the sump, passes it through the outer spray pipe to the inner spray device, and sprays it evenly downward onto the cooler, before falling back into the sump.

The direction of airflow is opposite to the downward direction of the spray water; therefore, it is called a counterflow closed cooling tower.

Natural wind enters the cooling tower through the inlet air louvers, flows upward, and is discharged from the top of the cooling tower through the exhaust system.

The spray pump draws water from the sump, passes it through the outer spray pipe to the inner spray device, and sprays it evenly downward onto the cooler, before falling back into the sump.

The direction of airflow is opposite to the downward direction of the spray water; therefore, it is called a counterflow closed cooling tower.

Our advantages:

1. All the pumps are from Hangzhou Nan Pump Industry, with a three-year warranty.

2. The inlet and outlet liquid pipes of the cooling tower and the flanges are connected by grooved clamps, enabling quick disassembly (facilitating later maintenance and repair).

3. The spray water tank is equipped with a heating device, which automatically heats up in winter when the temperature drops below 2 degrees, preventing the spray water from freezing.

4. The connection pipes of the water tank for the pumps are all made of 304 stainless steel. The entire cooling tower, except for the base channel steel, is made of stainless steel. The valves use turbine connect flange type, making it possible to directly disassemble the pump for later maintenance, and the water in the water tank and the pipes will not leak.

5. The main and backup pumps can automatically switch. The electrical control box has two soft starters to ensure stability and reliability.

6. Our spray pumps are made of stainless steel impellers. (Because the spray water of the cooling tower is usually well water or tap water, with poor water quality, the ordinary cast iron impellers have a very short service life.)

Meet the cooling needs in multiple fields

Cooling towers are mainly applied in industries such as casting, forging, injection molding, petroleum, chemical engineering, data centers, IT, medicine, textiles, rubber and plastics, food, electronics, and heat treatment.

| Model | Cooling Capacity | Main Circulation Pump | Fan | Spray Pump | Connecting Pipes (mm) | Equipment Size (mm) | Net Weight (Kg) | ||||||

| Power | Air Volume | Power (kw) | Flow Rate (m³/h) | Power (kw) | Inlet and Outlet | Make-up Water Inlet | Drain Outlet | Length | Width | Height | |||

| HFB-N10T | 50000 | 3*1 | 10000 | 0.37*1 | 11 | 0.75 | DN50 | DN20 | DN25 | 2200 | 1000 | 2300 | 350 |

| HFB-N15T | 75000 | 3*1 | 10000 | 0.37*1 | 11 | 0.75 | DN50 | DN20 | DN25 | 2200 | 1000 | 2300 | 500 |

| HFB-N20T | 100000 | 3*1 | 10000*2 | 0.37*2 | 22 | 1.1 | DN50 | DN20 | DN25 | 2400 | 1000 | 2300 | 650 |

| HFB-N30T | 150000 | 4*1 | 15000*2 | 0.75*2 | 22 | 1.1 | DN50 | DN20 | DN25 | 2400 | 1000 | 2500 | 750 |

| HFB-N40T | 200000 | 5.5 | 15000*2 | 0.75*2 | 28 | 0.75 | DN65 | DN25 | DN25 | 2400 | 1250 | 2300 | 850 |

| HFB-N50T | 250000 | 5.5*2 | 22000*2 | 1.5*2 | 53 | 1.1 | DN65 | DN25 | DN32 | 2800 | 1250 | 2600 | 950 |

| HFB-N60T | 300000 | 7.5*2 | 22000*2 | 1.5*2 | 53 | 1.1 | DN65 | DN25 | DN32 | 2800 | 1250 | 2700 | 1100 |

| HFB-N80T | 400000 | 7.5*2 | 22000*2 | 1.5*2 | 70 | 1.5 | DN80 | DN25 | DN32 | 2800 | 1500 | 2700 | 1300 |

| HFB-N100T | 500000 | 11*2 | 22000*3 | 1.5*3 | 80 | 2.2 | DN100 | DN32 | DN32 | 3400 | 1500 | 2800 | 1500 |

| HFB-N110T | 550000 | 11*2 | 22000*4 | 1.5*4 | 80 | 2.2 | DN100 | DN32 | DN32 | 2800 | 2000 | 2800 | 1500 |

| HFB-N120T | 600000 | 15*2 | 22000*4 | 1.5*4 | 100 | 2.2 | DN100 | DN32 | DN32 | 3400 | 2000 | 2800 | 1800 |

| HFB-N130T | 650000 | 15*2 | 22000*4 | 1.5*4 | 100 | 2.2 | DN100 | DN32 | DN40 | 3400 | 2000 | 2900 | 2000 |

| HFB-N140T | 700000 | 15*2 | 22000*4 | 1.5*4 | 100 | 2.2 | DN100 | DN32 | DN40 | 3400 | 2000 | 2900 | 2100 |

| HFB-N150T | 750000 | 15*2 | 22000*4 | 1.5*4 | 150 | 3 | DN100 | DN40 | DN50 | 3400 | 2000 | 2900 | 2200 |

| HFB-N160T | 800000 | 18.5*2 | 22000*4 | 1.5*4 | 150 | 3 | DN125 | DN40 | DN50 | 3400 | 2000 | 2900 | 2350 |

| HFB-N170T | 850000 | 18.5*2 | 22000*6 | 1.1*6 | 150 | 3 | DN125 | DN40 | DN50 | 3400 | 2000 | 3000 | 2500 |

| HFB-N180T | 900000 | 22*2 | 22000*6 | 1.5*6 | 150 | 3 | DN125 | DN40 | DN50 | 3900 | 2000 | 3000 | 2650 |

| HFB-N190T | 950000 | 22*2 | 22000*6 | 1.5*6 | 150 | 3 | DN125 | DN40 | DN50 | 3400 | 2300 | 3100 | 2800 |

| HFB-N200T | 1000000 | 22*2 | 22000*6 | 1.5*6 | 180 | 4 | DN150 | DN40 | DN50 | 3400 | 2500 | 3100 | 3000 |

| HFB-N220T | 1100000 | 30*2 | 22000*6 | 1.5*6 | 180 | 4 | DN150 | DN50 | DN50 | 3900 | 2300 | 3200 | 3250 |

| HFB-N240T | 1200000 | 30*2 | 34000*6 | 2.2*6 | 233 | 5.5 | DN150 | DN50 | DN65 | 4400 | 2300 | 3200 | 3500 |

| HFB-N260T | 1300000 | 37*2 | 34000*6 | 2.2*6 | 233 | 5.5 | DN200 | DN50 | DN65 | 4400 | 2500 | 3300 | 3750 |

| HFB-N280T | 1400000 | 37*2 | 34000*8 | 2.2*8 | 233 | 5.5 | DN200 | DN50 | DN65 | 4900 | 2300 | 3300 | 4000 |

| HFB-N300T | 1500000 | 37*2 | 34000*8 | 2.2*8 | 286 | 7.5 | DN200 | DN50 | DN65 | 4900 | 2500 | 3300 | 4250 |

| HFB-N350T | 1750000 | 45*2 | 34000*8 | 2.2*8 | 286 | 7.5 | DN250 | DN65 | DN50*2 | 5400 | 2500 | 3500 | 4500 |

| HFB-N400T | 2000000 | 55*2 | 34000*8 | 2.2*8 | 150*2 | 3*2 | DN250 | DN65 | DN50*2 | 5400 | 3000 | 3500 | 4800 |

| HFB-N450T | 2250000 | 55*2 | 34000*8 | 2.2*8 | 180*2 | 4*2 | DN300 | DN65 | DN50*2 | 5900 | 3000 | 3900 | 5200 |

| HFB-N500T | 2500000 | 34000*8 | 2.2*8 | 233*2 | 5.5*2 | DN300 | DN50*2 | DN50*2 | 6400 | 3000 | 3900 | 5800 | |

| HFB-N600T | 3000000 | 34000*8 | 2.2*8 | 286*2 | 7.5*2 | DN300 | DN50*2 | DN50*2 | 7400 | 3000 | 4200 | 6500 | |

Note: The dimensions of 10T and 15T are those of the integrated unit; those of 20T and above are the dimensions of the main unit; the external dimensions of all models can be customized.

The configuration of the auxiliary machine water tank is as follows: (Auxiliary machine size)

| 10-50T: 800-600-1800 (0.25m³ water tank); 50T-100T: 1100-1000-1800 (0.5m³ water tank); 100-200T: 1700-1100-1800 (1.0m³ water tank); Water tank elevated |

| 180T-260T: 2000-1600-1600 (1.5m³ water tank); 240-300T: 2100-2100-1600 (2.0m³ water tank) Water tank placed horizontally |

| 320T-400T: 2300-2100-1800 (3.0m³ water tank); 450-600T: 2500-2100-2200 (4.0m³ water tank) Water tank placed horizontally |

Online consultation

Attention: Please leave your email and our professionals will contact you as soon as possible!

Related products

CONTACT US

Address:Weicheng Economic Development Zone Weifang City Shandong Province.

PRODUCTS